First, we design a wax-rim teeth set-up try-in to determine the final result’s general esthetics. Once accepted, it is digitized and a pmma prototype is milled and glued to titanium bases. Your patient can then wear it for a few of weeks in order to make the necessary occlusal and esthetic adjustments.

Once the prototype has been adjusted and approved, it’s digitized once again. A final bridge is modeled and thanks to our Zirkonzahn teeth collection “Hero collection”, a realist structure is superimposed resulting in unequaled morphology. We then mill the final prosthesis with our 5 axle CAD/CAM machine using Prettau Zirconia blocks. To give it a natural aspect, we apply internal colourings in different tones (orange, brown, blue, pink as well as the Vita colours).The zirconia is then sintered in a high performance oven for 8 hours to obtain the desired 1400mpa hardness.

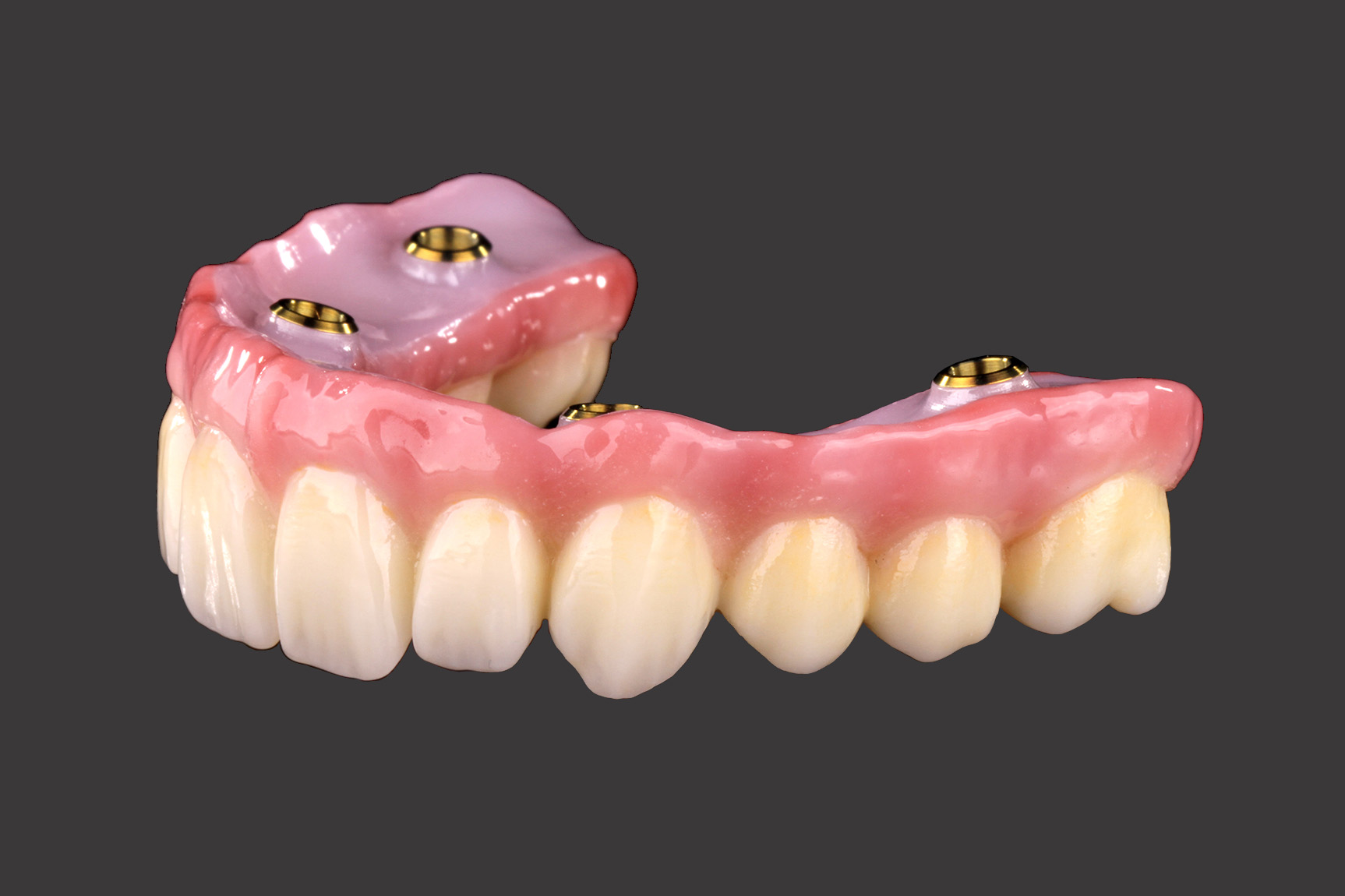

Finally, the ceramic is stratified to the buccal by an experienced ceramist in order to obtain the desired teeth and gum esthetics. Coloured titanium abutments are glued at the level of each implant for the metal’s resistance during tightening and in-mouth installation.