Zirkonzahn Italy has more than 150 employees, 8 branches and education center, exports in 80 countries and holds more than 12 patents all over the World. In addition to innovating, they manufacture all their products, burs, zirconia, porcelain scanners, software, milling machines, ovens, etc…

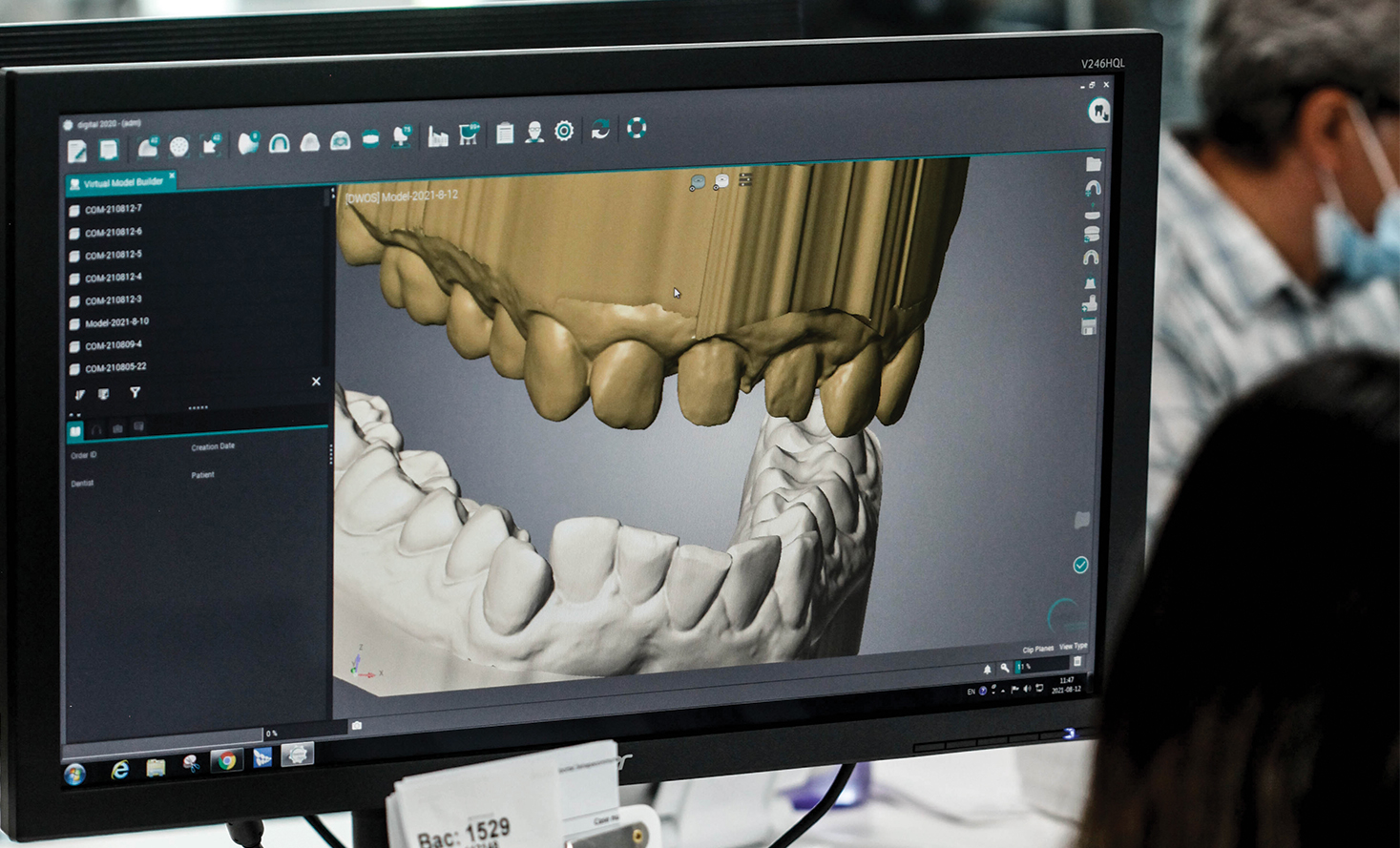

The Zirkonzahn System is a global concept developed by Enrico Steger. The Prettau zirconia is the most adaptable component for patients faced with diastema, bruxism or ceramic flaking problems, a solution not only functional but also esthetic. This perfectly bio-compatible material offers high translucency and a naturalistic look. Owing to these characteristics and a special coloration technique, ceramic stratification in functional areas can be avoided.